Machine for the manufacture of rubber hoses on rigid mandrel

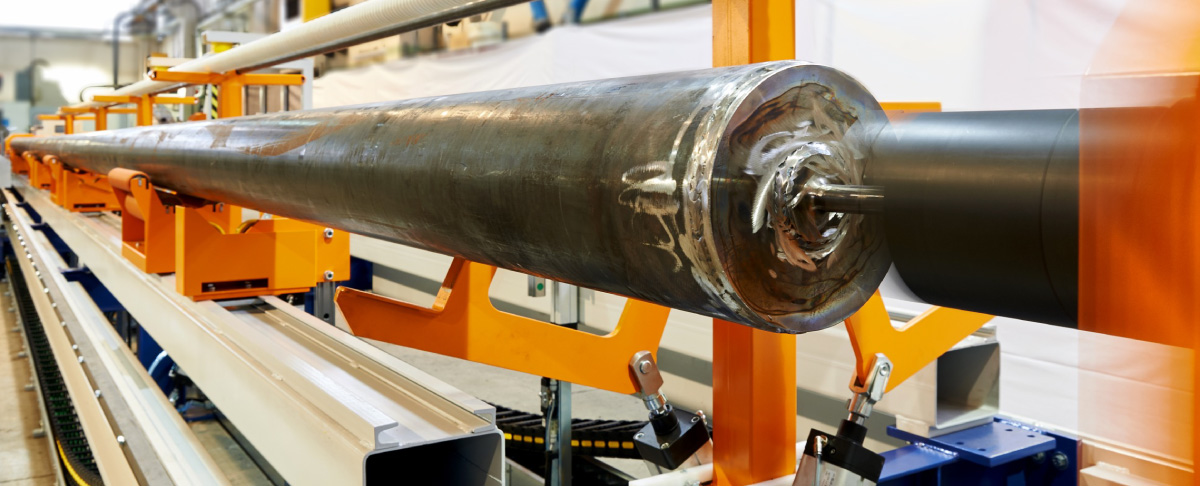

This machine, flagship of the PROJETMAN production, is made up of one or two motorized spindles, blocking, pulling and rotating the mandrel, resting on various mobile rollers supports according to the length of the hose to be produced. The various materials to be applied (rubber, tape, fabric, nylon rope, steel wire, etc.) are positioned on a trolley which runs along the frame to which it is attached. The only operator is on board the trolley and provides for its handling, as well as the replacement of the bobbins of materials, supported by a control panel that manages and records all the parameters and recipes of the hose to be produced.

Main features:

- Modular frame, adaptable to the desired length.

- Automatic lever system for loading and unloading mandrels/finished hoses and rack storage for mandrels and finished hoses (to limit the use of the bridge crane).

- Automatic lubrication devices and wet rollers for the mandrel.

- The trolley speed and mandrel rotation are synchronized through a dedicated SW.

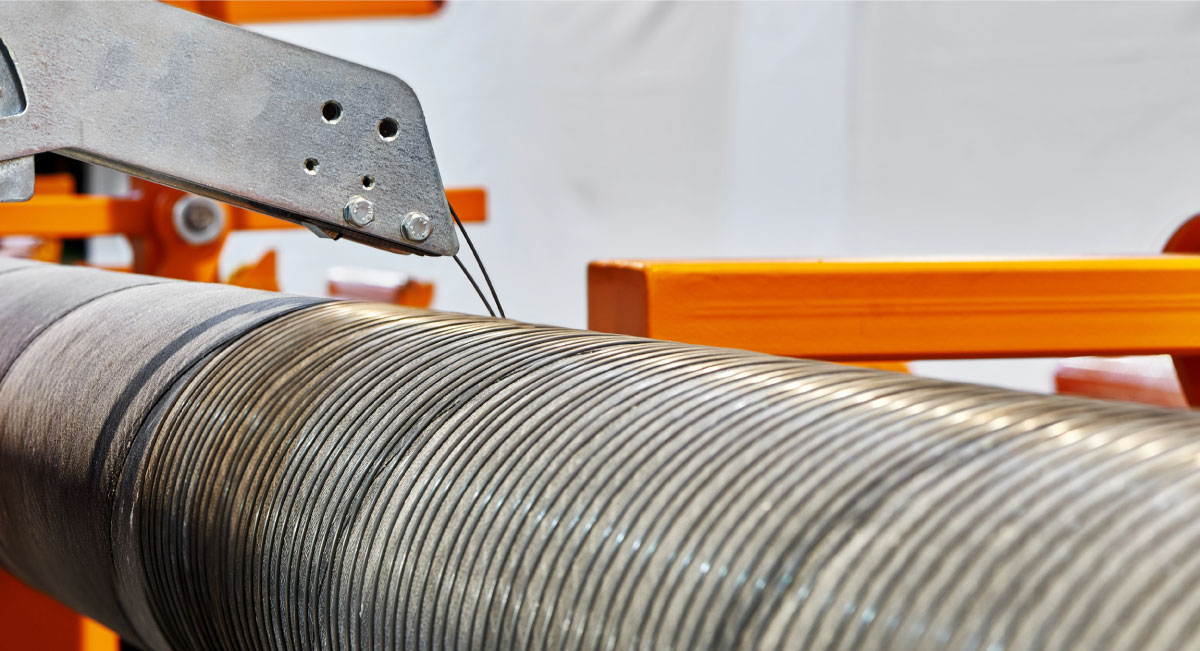

- Motorized devices for the application of rubber/rope/tape/steel wire.

- Safety devices, such as light courtains, laser scanners, fances and controlled accesses.

Technical features

Twin axis equipment for the manufacture of rubber hoses on rigid mandrel

Equipment for manufacture, on rigid mandrel, rubber hoses for low and medium pressure purpose.

Each equipment “TWIN” is made of two removing lines, also processing different kind of hoses at the same time.

Different kind of mandrels could be used: low carbon stell, stainless stell, chrome plated steel.

Spiral wrapping of various materials: rubber compounds, cord fabrics, steel wires (multiple helixes), according to the specifications of the hose’s project.

Delivery hoses with textile reinforcements, steel cord reinforcements; suction/discharge hoses with wire helixes and with smooth or corrugated cover; special purpose on demand hoses.

Liners of plastic materials (XL-PE, UHMW-PE), rubber compounds calendered with anti-adhesive or polythene film; cord fabrics, steel or nylon wires, nylon wrapping tapes and ropes.

All the materials should be rolled on a tubular media with fixed diameter, the steel wire should be coiled on a carrier.

| MACHINE | HM61S | HM61M | HM40S | HM40M | HM20B | HM16C | HM16GS1 | |

| Inside diameter: min. (mm.) | 13 | 55 | 13 | 55 | 100 | 250 | 102 | |

| Inside diameter: max. (mm.) | 65 | 205 | 65 | 205 | 305 | 612 | 609 | |

| Mandrel length: (mt.) | 61 | 61 | 40 | 40 | 20 | 16 | 16 | |

| Rotation speed: (rpm) | 0 - 600 | 0 - 450 | 0 - 600 | 0 - 450 | 0 - 350 | 0 - 350 | 0 - 300 | |

| Trolley speed: (mt./1’) | 0 - 70 | 0 - 70 | 0 - 70 | 0 - 70 | 0 - 70 | 0 - 50 | 0 - 30 | |

| EQUIPMENT | ||||||||

| Number of axis: | 2 | 2 | 2 | 2 | 2 | 1 | 1 | |

| Machine length: (mt.) | 69 | 69 | 48 | 48 | 28 | 26 | 26 | |

| Machine width (mt.) | 4,1 | 4,1 | 4,1 | 4,1 | 4,1 | 2,8 | 2,8 | |

| Machine heigth: (mt.) | 2,25 | 2,25 | 2,25 | 2,25 | 2,25 | 2,25 | 2,25 | |

| Electrical board dimensions: (mt.) | 2,4x0,5xh2 | 2,4x0,5xh2 | 2,4x0,5xh2 | 2,4x0,5xh2 | 2,4x0,5xh2 | 1,2x0,5xh2 | 1,2x0,5xh2 | |

| Overall weight: (Kg.) | 26000 | 26000 | 20000 | 20000 | 14000 | 8000 | 8000 | |

| Compressed air: Min. 0,5Mpa (nl./h.) | 200 | 200 | 200 | 200 | 100 | 100 | 100 | |

| Total installed power: (Kw.) | 40 | 50 | 30 | 35 | 35 | 20 | 30 | |