Decoilers for steel wire

Decoilers for steel wire on carrier on vertical axis

Each machine is made up of an unwinder on which a steel wire carrier and a winder for speed control are mounted on a vertical axis. The machine automatically releases the steel wire to the production line at the required speed.

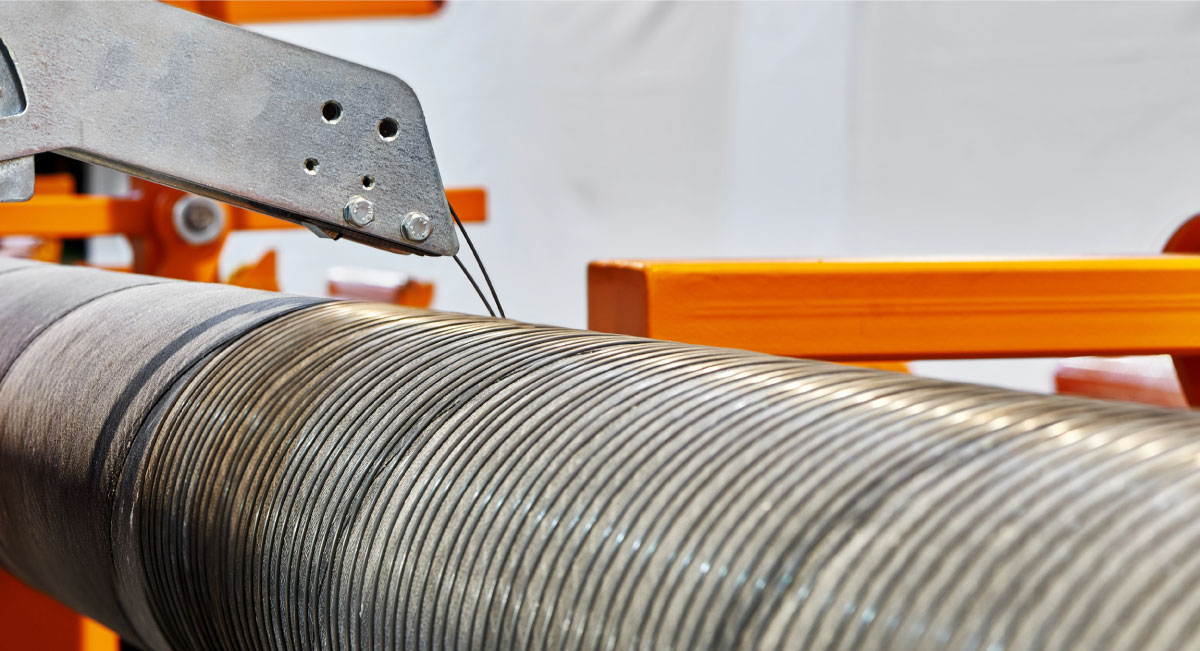

The steel wire is unwound from the carrier with constant traction and automatically modified speed, feeding the device for applying the metal spiral placed on the trolley of the hoses production machine.

Several wire decoilers can be installed serving the same production line or several production lines at the same time.

Decoilers for steel wire on bobbin on horizontal axis

The difference with the decoiler on carrier on vertical axis is that the bobbin unwinds the wire from the bobbin rotating on a horizontal axis.

Decoilers for two bobbins of steel wire on cart

This decoiler is mounted on a cart, attached to the main trolley. A pneumatic brake blocks the rotation of the bobbins, due to inertia. After the application of the steel wire, the trolley is detached from the main one and positioned at one end of the production line, where an operator can replace the bobbins, without interrupting the production of the hoses.