Accessory machines and devices

Vertical coiler for hoses

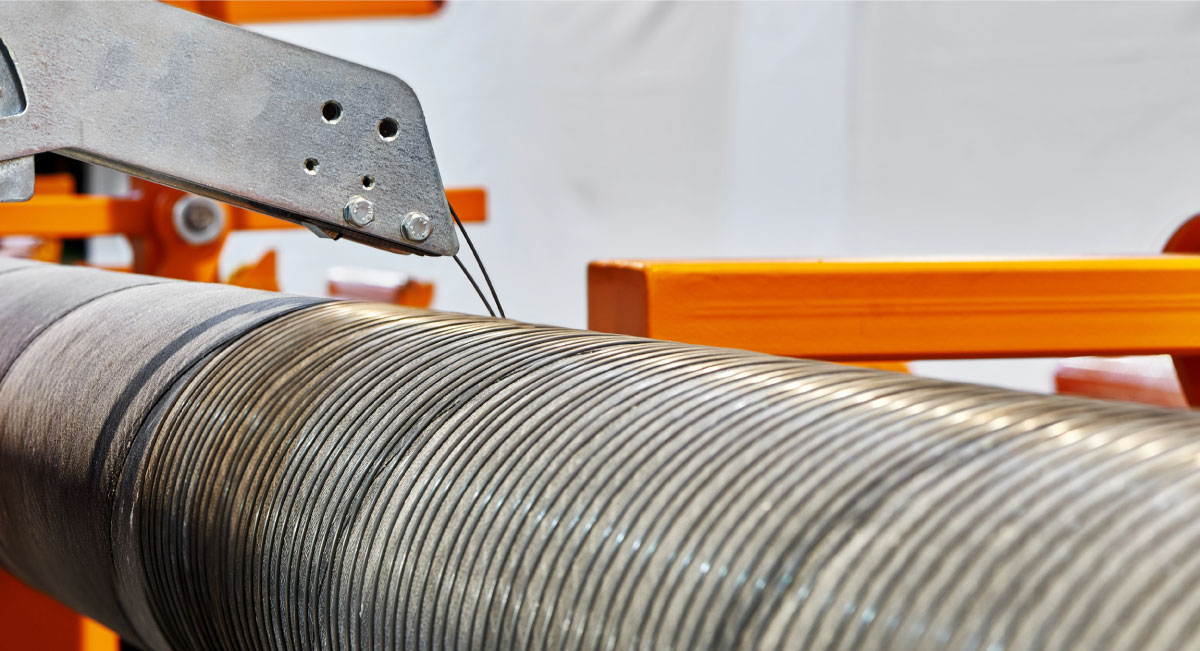

This machine is designed for the winding of flexible industrial rubber hoses on a variable diameter core and width.

The inner diameter of the coil is pre-set by the operator, via a touch panel interface, to ensure the suitable bending radius in order not to damage the hose. The set-up device moves the core’s arms to the proper position thanks to an Ac. Motor and a mechanic transmission.

Also the distance between the two flanges of the machine is pre-set by the operator via the touch panel interface, to configure the desired coil’s cross section according to the packaging specifications. The motorized axis sets the movable flange at the pre-set position and the winding process is ready to start.

A dedicated hook locks the end of the hose during the winding operation and easily releases it after the completion of the task.

After the operator has completed the binding, the inner core collapses to ease the picking of the roll.

A motorized stratifier, driven by the operator, guides the hose to the proper spiral’s position.

The coiling machine comprises:

- Base carpentry.

- Driven flanges.

- N. 4 self-positioning shields driven by A.c. motor and screw jacks.

- Self-positioning flange.

- Perimetric safety panels.

- Manual hose guide for the correct winding of the spiral.

- N. 1 Electric controls cabinet, compliant with IP 54 safety class and comprising: - Mains power cut-off device (Power supply 415 Vac. 50 Hz 3 Phase).

- Surge protection.

- Transformer for the auxiliary circuits.

- Control Techniques (EMERSON) Drives.

- Braking load resistances.

- Siemens S 7 – 300 CPU 314-2PN/DP PLC units.

- Siemens Touch HMI TP 700 COMFORT or similar Siemens model (HMI language: English).

- Emergency pushbutton.

- Measurement system: Metric.

Technical features

Vertical coiler for hoses

Roll up hoses for packaging.

The device is designed for the rolling of hoses with a present inner diameter, and a width according with standard packaging of the customer.

Dynamic Roll up of hoses.

Delivery hoses with fabric reinforcement, suction/discharge hoses with wire spiral and with smooth or corrugated cover.

| MACHINE | CP6165 | CP61130 | CP4065 | CP40130 | |

| Hoses outer diameter: Max. (mm.) | 65 | 130 | 65 | 130 | |

| Coil inner diameter: (mm.) | 260 - 600 | 360 - 800 | 260 - 600 | 360 - 800 | |

| Coil outer diameter: Max. (mm.) | 1200 | 1850 | 1200 | 1850 | |

| Coil height: Min. (mm.) | 50 | 100 | 50 | 100 | |

| Coil height: Max. (mm.) | 300 | 400 | 300 | 400 | |

| Machine length: (mt.) | 2,4 | 2,4 | 2,4 | 2,4 | |

| Machine width: (mt.) | 1 | 1 | 1 | 1 | |

| Machine height: (mt.) | 1,8 | 1,8 | 1,8 | 1,8 | |

| Electrical board dimensions: (mt.) | 0,8 x 0,3 x h0,8 | 0,8 x 0,3 x h0,8 | 0,8 x 0,3 x h0,8 | 0,8 x 0,3 x h0,8 | |

| Total installed power: (Kw) | 7,5 | 7,5 | 7,5 | 7,5 | |

Technical features

Machine for cord fabric ripping

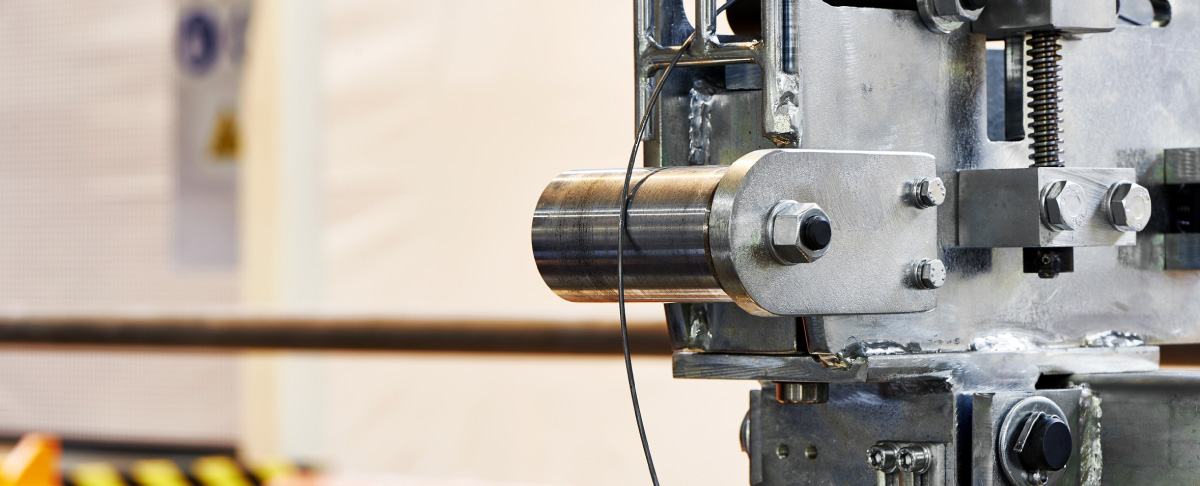

Rubber coated cord fabrics ripping and winding into specific widths and lenghts.

The equipment is feeded with rubber coated cord fabrics roll from calender and ripped into smaller widths.

Dynamic ripping of cords.

Yarns with different densities and tenacities; with or without adhesion enhancement.

Rayon, Nylon, Poliestere, various textile cords.

All the materials should be rolled on a tubular core. Final set-up in accordance with the standards of the customer.

| MACHINE | TRM70 | TRM100 | |

| Fabric width: Max (mm) | 700 | 1000 | |

| Roll diameter: Max. (mm.) | 600 | 600 | |

| Roll weight: Max (kg.) | 800 | 800 | |

| Fabric ripping linear speed: (mt./min.) | 5 - 200 | 5 - 200 | |

| Machine length: (mt.) | 3,3 | 3,6 | |

| Machine width: (mt.) | 1,05 | 1,05 | |

| Machine height: (mt.) | 2,15 | 2,15 | |

| Electrical board dimensions: (mt.) | 0,6 x 0,3 x 1,2 | 0,6 x 0,3 x 1,2 | |

| Total installed power: (kw.) | 10 | 10 | |

Technical features

Bridge cranes and lifters for mandrels

Place and remove the mandrels on and from workstations: storage of the mandrels, production lines, autoclave, lines for the removal of belts and ropes, lines for the extraction of the hoses.

The equipment consists of a special bridge crane, equipped with a system for lifting a beam that supports the mandrels, a system of transversal translation and of a possible system of longitudinal translation.

Lifting and moving the mandrels.

Different kind of mandrels could be used: low carbon steel, stainless steel, chrome plated steel.

Specific and customized based on Customer specifications.